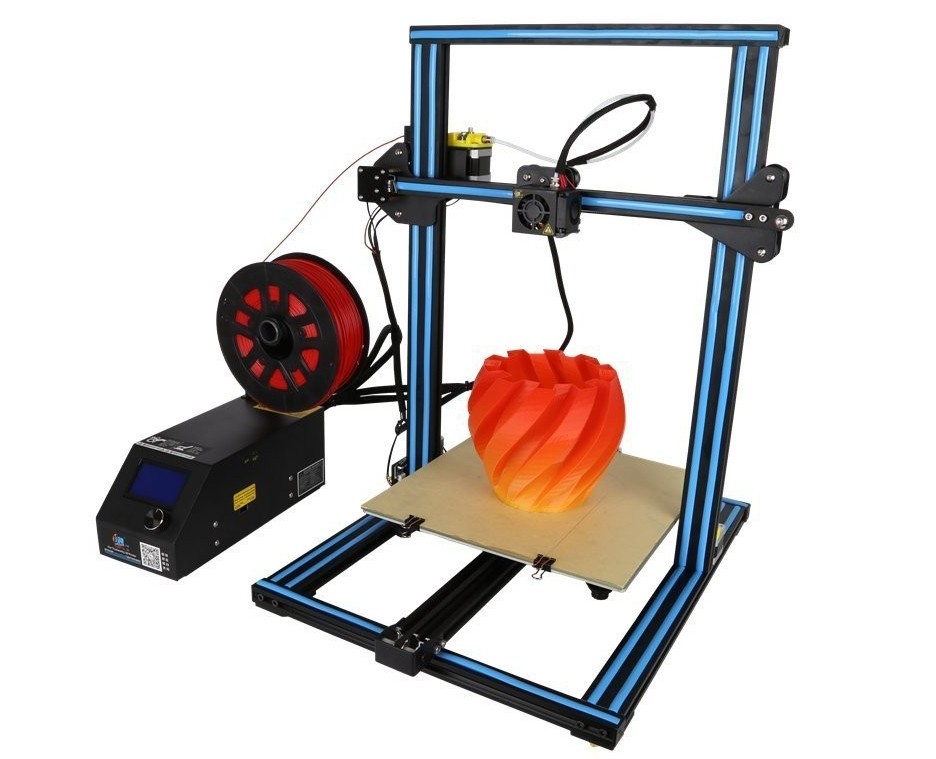

Creality 3D CR-10S Review

Our Verdict

Our Analysis and Test Results

Performance Comparison

To see which 3D printer is truly the best, we purchased the top models available on the market and tested them head-to-head to find the best. In total, we printed dozens of models on each printer and compared them to determine scores, as well as looking at the effort associated with changing filament, setting up and calibrating each printer, and its capabilities. These tests were divided up among four weighted rating metrics — Print Quality, Print Capabilities, Support, and Ease of Use — with the sections below describing the performance of the Creality CR-10S and how it stacks up against the rest of the printers in the group.

Print Quality

Accounting for the largest portion of the total score, the Print Quality metric is responsible for 40% of the final score. To score the Creality, we printed a suite of models in both PLA and ABS and compared the finished prints side-by-side to the rest of the prints. We used the default setting, only making minor tweaks if necessary to get the model to print. The Creality did very well, meriting a 7 out of 10 for its showing.

The first model that we evaluated was a small tugboat known as 3D Benchy, which is commonly used as a 3D printer “torture test”. This printer got off to a great start in this series of tests, creating a great Benchy in both PLA and ABS. There were only some slight aberrations in the overhanging sections and the text on the base layer lacked some definition, but it was otherwise an essentially perfect little boat.

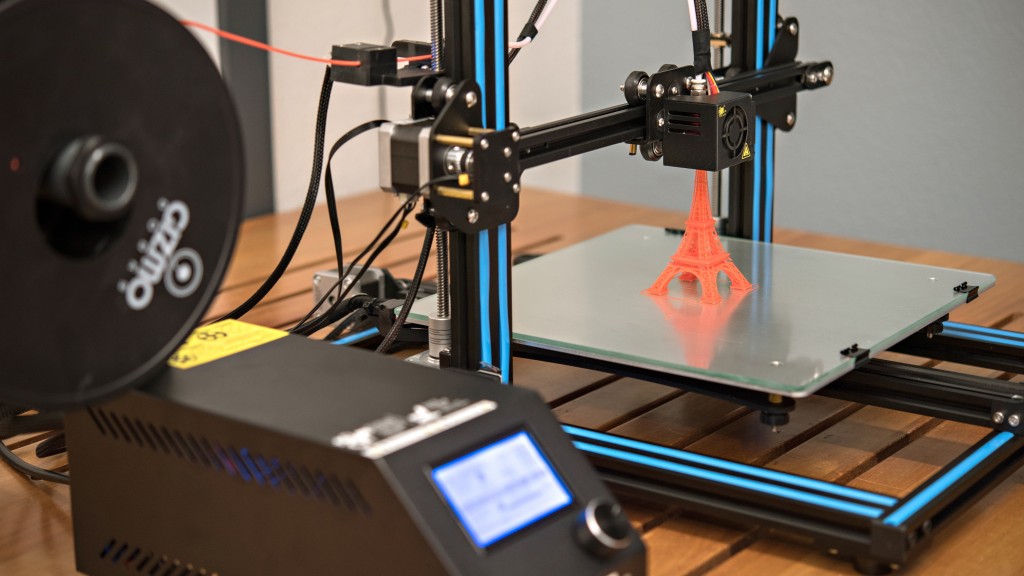

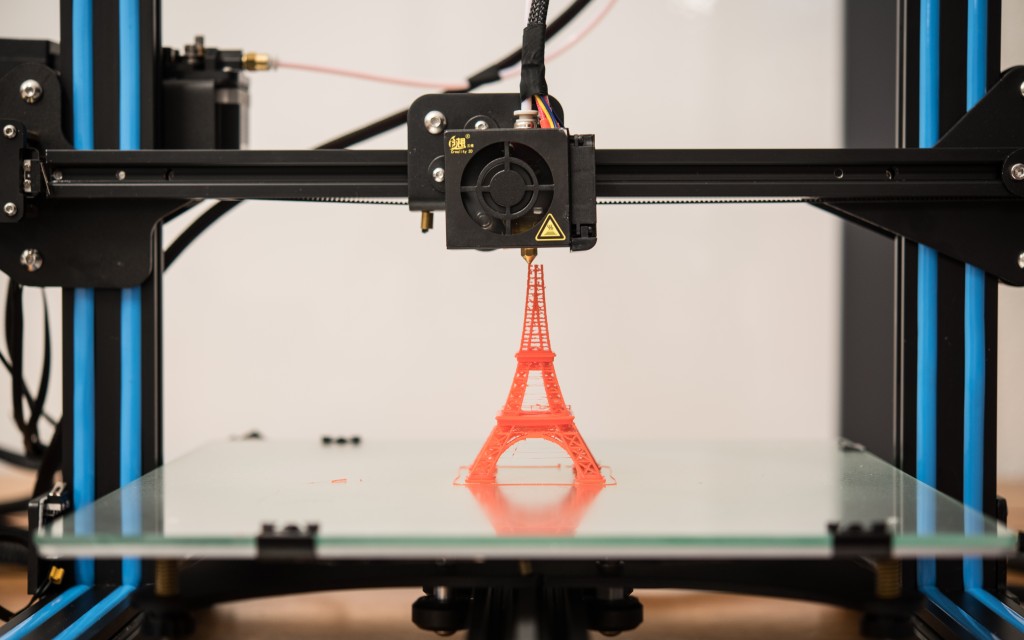

Next, we scored some of the most difficult to print models in the group: the Eiffel Tower and a spiral bridging test. The CR-10S made an amazingly high-quality bridge model in PLA, with very smooth layers. There was only a minuscule amount of sag in the longest bridge, with only a few additional strings. The quality dropped a little in the ABS version, with a bit more sag in the longer bridges and the entire print displaying some warpage.

The Eiffel Tower in PLA was mediocre, matching that produced by the Monoprice Maker Select. The ABS version kept failing and breaking apart.

The next three model we evaluated were our bridging and nickel tests, as well as an articulated elephant model. The PLA elephant was exceptionally well done, with very clean ears and other details. The articulated joints were totally free and unobstructed, with almost no effort required to initially break them free. The ABS version came out a little worse, due to some layer separation, but the legs still moved freely. The Creality is reasonably dimensionally accurate, with the nickel test piece only coming out a tiny bit larger than the nickel in both types of plastic.

The overhang test model produced by the CR-10S in PLA was absolutely perfect, with exceptionally clean overhanging faces. It came out a little more disfigured in the ABS version, exhibiting some substantial undulations on the steeper overhangs.

Next, we scored the hollow cube and the articulated platform jack. The PLA wireframe cube was excellent, with only a minuscule amount of wobble, but the ABS version suffered from severe layer separation, with the top breaking off of the cube with the lightest tap. The PLA platform jack matched the quality of the Ultimaker, moving very freely with hardly any print defects. The ABS version still articulated, but had a decent amount of layers separating, hurting its score slightly.

The next two prints are of a pair of low-poly figures from popular video games. The CR-10S did a phenomenal job creating both of these models in PLA, matching the showing of the Ultimaker. However, there was a decent amount of layer separation in the ABS versions.

Continuing on, we looked at a trio of test prints. We looked at a spiral vase, a tall tower, and a support test. The Creality again produced an excellent PLA spiral vase, but the ABS version did show some layer separation. The support test turned out great in both PLA and ABS, with relatively smooth supported faces and a support matrix that was very easily removed. Both the tall towers also came out great, with only a tiny bit of Z-axis wobble present.

Finally, the last two prints we evaluated were a threaded jar and lid.

The PLA jar came out exceptional, with its corresponding lid right behind it. The lid had decent resolution, but did show some errors. However, it still easily threaded on the jar. The ABS jar and lid weren't quite as nice, with some layer separation and the lid having plenty of strings.

Ease of Use

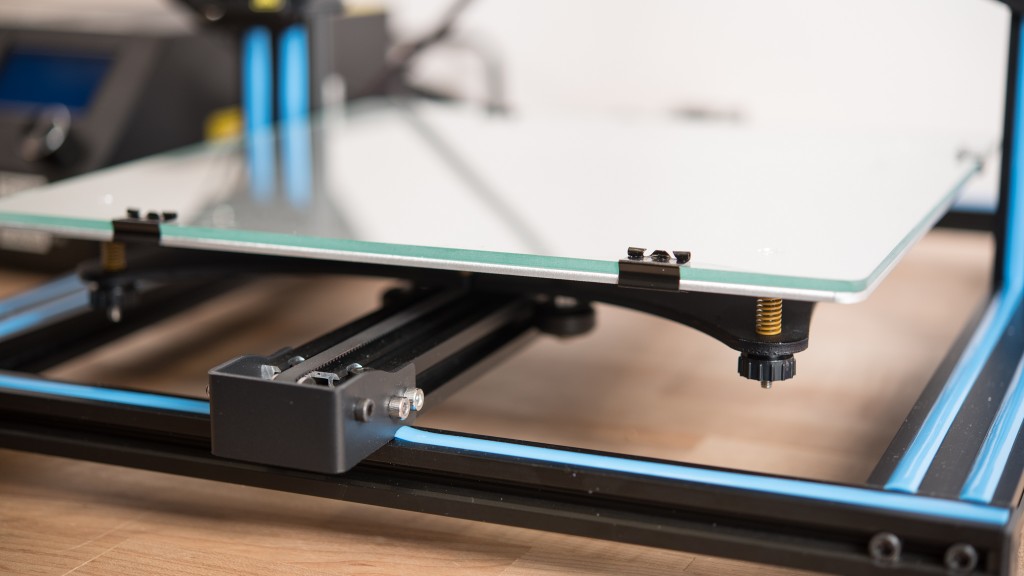

Our next metric, Ease of Use, is responsible for 30% of the total score. We ranked and scored each printer on how much effort it took to unbox and setup, as well as how much work it took to change filament and level the build plate. We also evaluated how you connected to the printer and the quality of the display on each one. The Creality performed reasonably well, earning it a 6 out of 10.

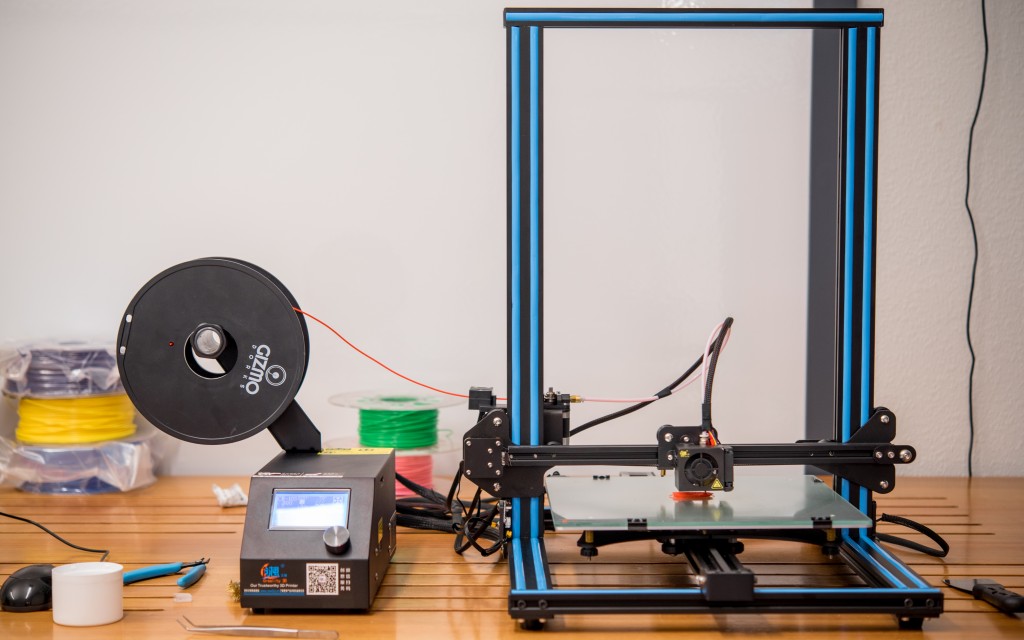

The initial assembly of this printer is definitely a little on the complex side. The included documentation isn't the best and is split between digital resources on the included SD card and printed instructions that aren't very easy to follow. You need to first attach the vertical frame to the horizontal frame, add the glass to the print bed, then connect all the wires, then mount the spool holder, and finally attach the filament sensor.

We definitely had to search online for some additional information to aid in putting it together. It's not an impossible task — even for the complete 3D printer novice — but definitely is far from a turnkey printer.

Thankfully, leveling the bed is a much easier task. The process is semi-automatic, with the Creality automatically moving the nozzle to the correct location, then leaving you to manually turn the knobs to correctly set the height.

This is very similar to the Ultimaker, with the main difference being that the Creality will time out and return to the home screen if you take too much time before moving onto the next step.

It's decently easy to swap filament, though the process is not automatic. You need to set the extruder to heat up, then manually pull the old filament you. You can then feed in the new filament while holding down the extruder lever or engage the motor to do it for you. We did find that it usually took a few tries, as the filament would get hung up, and we would have to pull it out and straighten it before trying again.

Files can be sent to the Creality by USB cable or microSD card — no wireless options.

The display is decent, showing the time elapsed, percentage completed, and a few other metrics while printing.

Print Capabilities

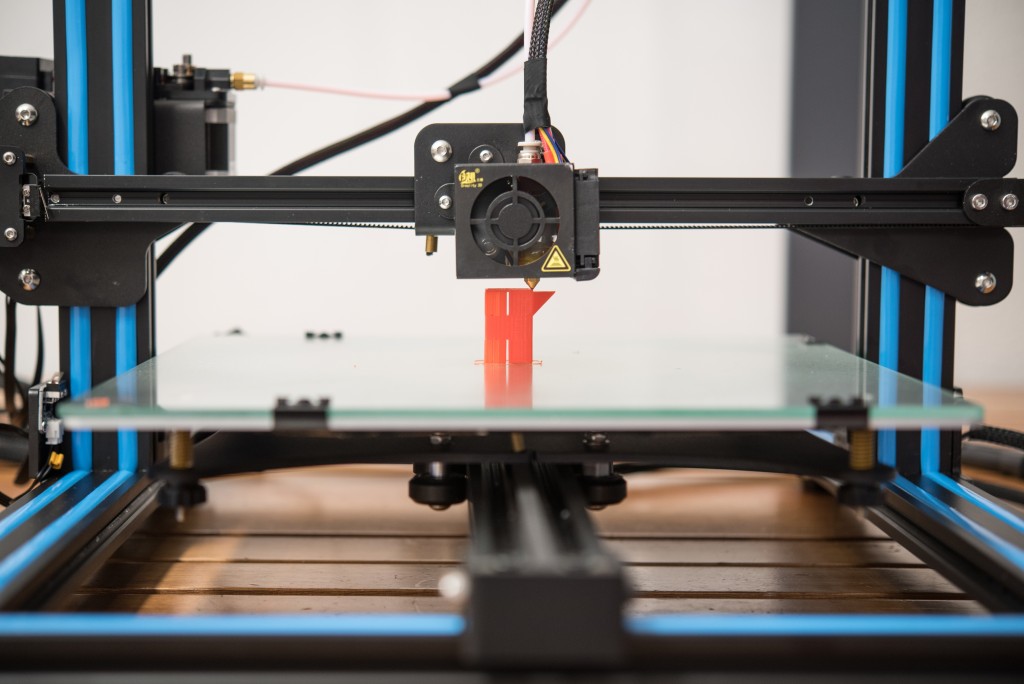

Accounting for 20% of the total score, our Print Capabilities metric is based on the build envelope, the quality of the build plate, the temperature and filament capabilities of the printer, the number of cooling fans, and the software used. The Creality scored exceptionally well in this metric, netting one of the best scores that we have seen.

The Creality has an absolutely massive build area, measuring in at 11.81"x11.81"x15.75" (300mmx300mmx400mm). This is the largest of the group by far, allowing you to create some absolutely massive prints. The print bed is glass, with some included masking tape that you can use, though we primarily used either hairspray, blue painter's tape, or an ABS acetone slurry to improve bed adhesion.

This printer works with 1.75mm filament and isn't restricted to a proprietary brand. Its extruder can reach a maximum temperature of 260°C, making it suitable for a wide variety of filaments, such as ABS, PLA, TPU, wood fill, or PETG. The bed can reach a temperature of 135°C and it has both an extruder and layer cooling fan.

The documentation recommends using Cura as a slicer, but also mentions that it is compatible with Repetier-Host. These programs are both free to download. This printer is also compatible with Simplify3D — a slicer that offers increased performance and control, though it costs about $150. We used Cura for our testing.

Support

Finally, we graded the quality of the customer support for each printer. This metric accounts for the residual 10% of the total score. The Creality scored very poorly, earning a 2 out of 10 for its paltry performance.

Essentially, there isn't any customer support for this printer and you are on your own. We never managed to contact them and the only online videos we found were posted by other users, not by Creality itself. Supposedly, this printer has a 1-year limited warranty, but as we weren't ever able to contact them, the benefits of this are somewhat suspect.

Value

This printer is a fantastic value, holding its own with printers that cost 4-5 times as much.

Conclusion

All in all, if you are searching for a 3D printer on a budget, you can't go wrong with the Creality CR-10S. This inexpensive printer has an enormous build area and produces prints that are exceptionally high-quality. However, the customer support is pretty much nonexistent, so you should be prepared to troubleshoot any issues you have yourself or by searching through forums and other resources online to find the answer.