3D printing got its start in 1981 when a Japanese scientist created three-dimensional plastic models with layers of photo-hardening thermoset polymer. Needless to say, the idea took off. These days there at least seven different ways the systems work and you can have one of your own for several thousand dollars or less than $500.

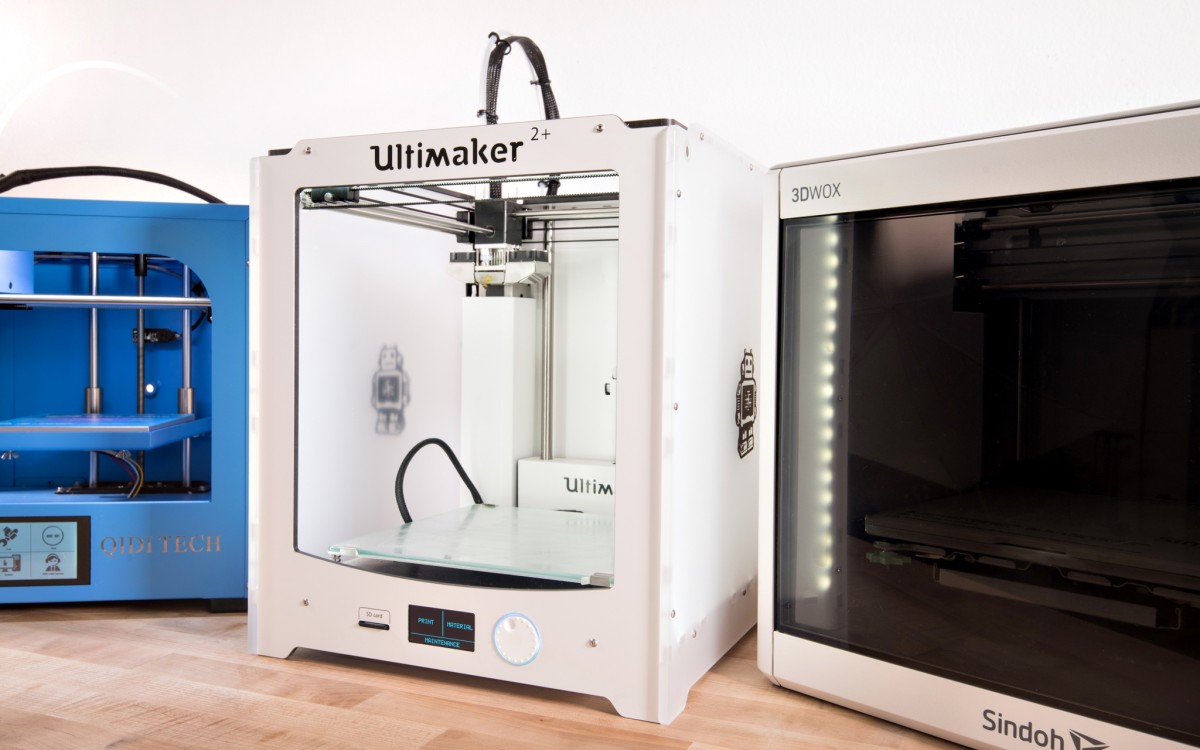

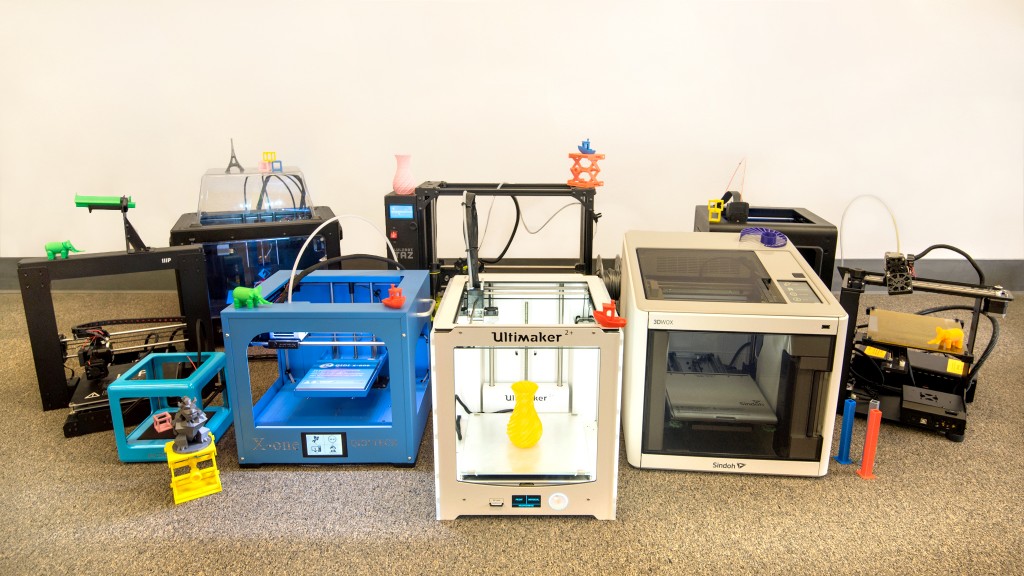

TechGearLab is here to help sort out the selection process. We bought 10 of the most popular models and put them through exhaustive side-by-side testing. Check out the results if you are just starting or are an expert user. For more information on specific models, take a look at the complete results of our comprehensive best 3D printer review.

Why Buy a 3D Printer?

At the high end, these machines may over time revolutionize manufacturing, print food or make replacement organs and tissues. Today at the consumer level the machines that are typically found in homes or small studios will take a 3D file from a computer and produce a physical model of it in plastic. This can take minutes to hours to days, depending on the size of the model and the technology of the printer. You can make custom mounts, replacement parts, educational models, household items or your very own personal army of squirrels or action figures.

Step 1: Buy or Build?

Start by figuring out whether you would be best served by a model that is ready to go out of the box, one that has some assembly required, or a kit model that you build from the ground up. Each of these types has advantages and disadvantages.

Getting a printer ready to go out of the box will cost a bit more, but you can print something quickly with most of the calibration done at the factory. Check the bed level to see that nothing shifted in shipping but other than that, you are ready to go. One downside: this essentially locks you into bed with the manufacturer for any support, because in most cases disassembling or working on the machine yourself will void your warranty. Cautionary note: it's not uncommon for sales material to show a completed printer when what you get is a disassembled kit.

Some models, especially the larger ones, ship with most assembly completed, meaning you can probably be ready to go in one or two hours. You may need a few common tools if they were not included, and you need to take a close look through the directions, but most people should be able to get off the ground with relative ease having bought either a completely assembled printer or a partially assembled one. All of the models in our review fall into these categories.

This leaves the final type of printer: home-built from a kit. This is definitely NOT the way to go for most people. However, for tech-savvy tinkerers this method has several benefits. Kit printers usually get you more printer for your dollar and are much easier to upgrade and add extras to. You also are intimately familiar with your printer and are much more likely to be able to repair it, should the need arise. Do know that it takes a significant amount of time to build, a few less-than-common tools, and another significant chunk of time to calibrate — all this before you start printing anything. This is a good option only if you look at getting a 3D printer as a project — not as a tool.

Step 2: What Type of 3D Printer Should You Get?

While all of these products take a digital file and create a physical manifestation of it, they go about it in different ways. The exact methods and specifications of the main types are outlined later but most users will hear two main types thrown around: FDM/FFM/FFF, and SLA.

The first methods — FDM/FFM/FFF — is the most common method for most home or consumer grade 3D printers. This technology has a ton of different names — Fused Deposition Modeling, Fused Filament Method, Fused Filament Fabrication are three of them. They all rely on plastic filament being forced through a heated nozzle that moves on a gantry. The model is built up, layer-by-layer, until it is completed.

This type printer is great for most new users, as well as for a large chunk of intermediate and advanced users. All the printers in our review use this type of fabrication technology. This method does have drawbacks, such as a limit on the resolution available, difficulty with printing thin objects, and struggles with overhanging models.

This can be helped by printing with support — a sacrificial, breakaway

structure — but this can be difficult to get right and removal can be a gigantic pain.

SLA printers start where FDM/FFF printers stop, with SLA printers' lowest level of resolution on par with the highest available on FDM. These printers use a tank of resin or other similar substance, then use a laser to cure it. The model is still built layer-by-layer but this method of fabrication makes exceptionally detailed structures with a great surface finish. These printers can also handle delicate geometries and overhanging parts with ease.

However, while SLA printers have unparalleled detail, they are usually more expensive initially, have a higher cost per print, and have a steeper learning curve. These machines probably are not the best choice when you are starting out unless you are a jeweler, artist or someone who definitely needs this level of resolution and are willing to pay a premium for it.

Step 3: New to 3D Printing? Prioritize Ease of Use.

3D printers are a fairly new technology and even the most user-friendly model will take quite a learning curve, whether it's finding models to print, learning the meaning of all the setting in the slicing software, learning what slicing software is and why you need it, picking the right type of filament, or 3D ink, and discovering the limitations of your printer. This may sound overwhelming, but it is doable with a bit of research and practice.

However, it is important to not overestimate your technical skill level and overall technical savviness. Getting a bargain deal on a 3D printer is great but can end up costing more in frustration when it proves to be extremely unreliable and requires constant maintenance. If you don't have the skills or patience to work on the printer, you will end up spending more time cursing the printer than using it. Established companies that have reliable customer service and support will be much more helpful at answering questions, have more detailed and complete documentations, and have an established protocol for repairing or replacing parts of your machine if it breaks, even though these models may cost slightly more.

Less expensive models from overseas based companies may come at a bargain price, but you may be largely on your own or stuck without proper documentation and watching videos on the internet. New users should get a model that scores well in our Ease of Use metric as well as our Support and Reliability metric.

Step 4: Advanced Features or Other Special Concerns?

Your final choice should involve looking at any special features that you want. If you want to print BIG things, then getting the model that has the largest printable volume is a good idea. However, many software programs allow you to split large models into sections for easy printing with smaller machines. Models that have at least an 8"x8"x8" build area will be able to print the vast majority of models without splitting and this is a good, middle-of-the-road build envelope to start with.

Also, consider how much space you have for your new printer. Smaller models with correspondingly smaller build areas will fit on a portion of your desk or a small table. Larger models need a significant amount of real estate — a dedicated station or workbench. In addition to the printer itself, you need some space for storage of filament and a small assortment of tools…and space to display all your newly 3D printed knick-knacks.

Finally, you can look at the temperature range or filament types that work with the printers you are considering. The temperature range of the extruder will dictate what materials you can print with, whether you are limited to the two most common plastics: PLA and ABS, or if you can branch out to specialty materials with unique properties such as nylon, carbon-fiber-filled, wood-filled, bronze-filled, PETG, or T-Glase.

You also want to check if the printer is compatible with generic filament or will only work with the manufacturer's supply. It usually is slightly more expensive but less of a hassle to have a printer that works with proprietary filament; that way you can use preset settings. However, with proprietary filament you are restricted to the selection available from the manufacturer, which may not include those specialty filaments listed above.

Take a look at our How We Test article for a more detailed breakdown of our testing and evaluating process or our comprehensive 3D Printer review to see which models came out on top and why. The next sections give some more background information on the various types and technologies of currently available printers, as well as different ways to get files to print.

Other Types and Technologies of 3D Printers

In addition to FDM/FFF and SLA mentioned there are a few other types.

Handheld

Excited about 3D printing but don't want to spend hundreds of bucks? Consider a 3D printing pen. These are mainly toys and will not produce physical objects anywhere close to the quality from a 3D printer, but they are a fun way to play with the technology for less than $50.

SLS

Selective Laser Sintering, or SLS is a highly precise method of 3D printing. Parts are formed by a laser sintering, or melting together, a powdered material to form a cohesive object. These printers can actually print metal objects, using a high-powered laser to fuse metal powder. As you can imagine, these machines are complex, expensive and mainly suited to labs, studios or other industrial applications.

Emerging Technologies

The technology behind these machines is constantly evolving, whether it is bioprinting replacement organs or printing at lightning fast speeds using Terminator-inspired ideas. As with most cutting-edge technologies, there is a noticeable lag between the development of these techniques and their incorporation into consumer products. For now, home 3D printers will primarily print plastic, using FFF or SLA technologies…or print pancakes, of course.

How to Find Things to Print

There are endless possibilities of things you can make on your new machine. Here are places where you can find them.

Online File Repositories

One of the easiest places to get 3D files to print is to download them directly from the internet. Many of these sites, such as Thingiverse, one of the most popular online 3D printing communities, or Pinshape, an up and coming site that is growing more and more popular. These sites offer tons of files for free, usually under an open source license. In addition to offering files, these sites will occasionally host contests and challenges with prizes. There are tons of options; these sites are two of the most prominent.

Draw Your Own

Bored of printing other designers' work? Can't find what you are looking for? Then it may be time to take up drawing your own using a CAD, or Computer Aided Design program. While professional CAD programs can cost tens of thousands of dollars and take years to learn, there are a handful of free programs that aren't too difficult to learn, such as Google Sketchup, TinkerCAD, and Blender. Sketchup and TinkerCAD have reasonably shallow learning curves, while Blender can be quite intimidating for the novice. Luckily, there is an enormous selection of online resources or classes that teach these programs.

3D Scanning/Photogrammetry

The final method to create a 3D file is by scanning, using a 3D scanner (or a 3D scanning attachment for your mobile device) or by photogrammetry — a process for combining many 2D photos of an object into a 3D printable file. Scanners have mixed results and can represent a significant investment, ranging from a few hundred bucks to several thousand. Photogrammetry works well with simple objects, with many apps and programs able to accomplish this task, but can struggle with more complicated ones. Some of the newer 3D printers even have a built-in scanner, allowing them to act as a sort of 3-dimensional photocopy machine.

Conclusion

Our complete review is linked below, or you can peruse our How We Test article for a comprehensive look at our testing and ranking procedures.